It’s been a quite a year for the bike industry with dramatic increases in cycling and the world running out of bikes to sell. We are being told by some of our suppliers that we will need to pre order for 2022 as the availability of bikes will be limited for the foreseeable future as production is rationed. We have a long list of people wanting bikes and so we thought it was time to look at custom building as one of our customers was asking for a gravel bike with flat bars, that could do ‘…long distance as well as trail riding…‘. She is about 5’ 9”, is an experienced rider and lives in Cumbria so is remote from Spindles. We hope to document the process in these blog pages so this is the first entry post.

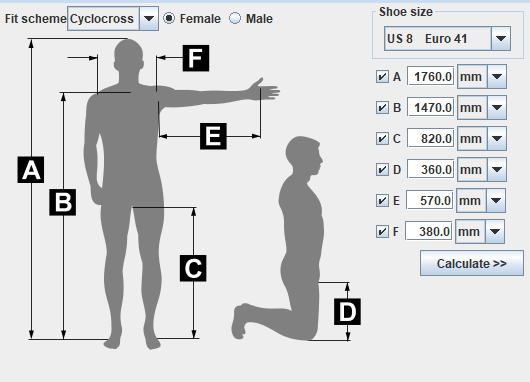

Tom is our frame builder who owns Barbastelle which is our inhouse brand. Tom has been building frames for a number of years and exhibits at Bespoke. The first part of the process is to get some dimensions which were ‘customer produced’ and then plug them into Bike CAD.

We are working to a schedule that puts the building process in January 2021 so there is plenty of time to have an iterative process that converges on a design that satisfies all the requirements. We start the process with a ‘first cut’ design that we can take back to the customer for comments.

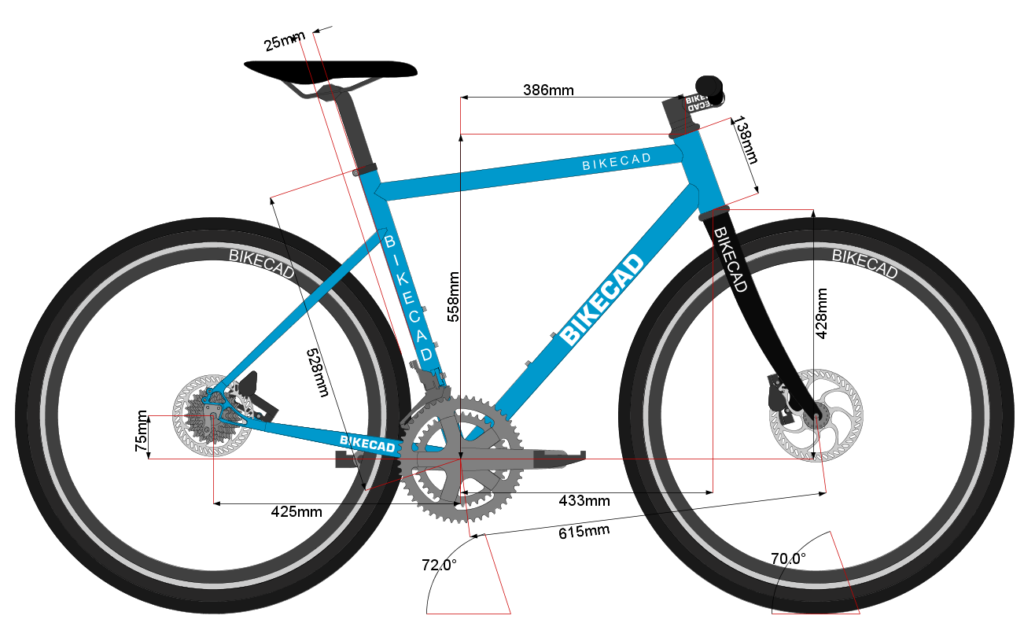

We want a flat bar Gravel bike with a sloping top tube and seat stays that attach just below the top of the seat tube. We initially decided on a 70 degree head tube angle to provide stable handling and 72 degree seat tube angle for comfort. The bike needs to be able to fit 650B x 47mm and 700C by up to 40mm tyres the idea being that that long distance can be done on 700C while trails can be done on 650B.

The decision to implement quick release dropouts over thru axles was driven by availability coupled and customer familiarity. Thru axles are becoming increasingly popular but standards have yet to fully converge however, in this case familiarity was a driver. The rear dropouts also incorporate mudguard and rack fittings. We already had a suitable set of forks that would give the required tyre clearance and mudguard fittings so this was programmed into BikeCAD together with a reach that would give good toe clearance. The initial deign gave an effective seat tube size of 55.6cm which feels about right for a 5′ 9” person and is presented below with 650B x 47mm tyres.

The next post will work on the tube details together with component selection.